From All About Circuits:

Brushless DC motors are similar to AC synchronous motors. The major

difference is that synchronous motors develop a sinusoidal back EMF,

as compared to a rectangular, or trapezoidal, back EMF for brushless

DC motors. Both have stator created rotating magnetic fields producing

torque in a magnetic rotor.

Construction wise, there is essentially* no difference.

The motor in the above diagram could be called an "AC Induction Motor" or a "Brushless DC Motor" and it would be the same motor.

The main difference is in the drive. An AC motor is controlled by a drive consisting of a sinusoidal alternating current waveform. It's speed is synchronous with the frequency of that waveform. And since it is driven by a sine wave, it's Back-EMF is a sine wave. A single phase AC Motor could be driven from the wall socket and it would turn at 3000 RPM or 3600 RPM (depending on your country of origin having 50/60Hz mains).

Notice that I said could there. In order to drive a motor from a DC source, a controller, which is essentially just a DC to AC inverter, is required. You are correct in stating that AC motors can also be driven by controllers. For instance a Variable Frequency Drive (VFD) which are, as you said, DC to AC inverters. Although typically they have an AC to DC rectifier front end.

PWM VFD http://www.inverter-china.com/forum/newfile/img/PWM-VFD-Diagram.gif

VFDs use PWM to approximate a sine wave and can come pretty close by varying the pulse widths continuously as seen below:

While using PWM to approximate a sine wave would produce a nearly sinusoidal Back-EMF wave form ("fuzzy" is the word you used), it's also a bit more complicated to do. A simpler commutation technique is called six-step commutation in which the Back-EMF waveform is more trapezoidal than sinusoidal.

six-step Back-EMF http://www.emeraldinsight.com/content_images/fig/1740300310012.png

And while this "PWM is really poor" as you said, it's also a lot simpler to implement and therefore cheaper.

There are other methods of commutation besides six-step and sinusoidal. The only other one that is really popular (in my opinion) is space vector drive. This has about the same complexity as sinusoidal drive but make better use of the available DC bus voltage. I'm not going to go into detail on space vector as I think it will only muddy the waters of this discussion.

So those are the differences in the drive techniques. The waveform used to drive AC motors is typically sinusoidal and could come directly from an AC source or could be approximated using PWM. The waveform used to drive DC motors is typically trapezoidal and comes from a DC source. There is no reason why the drives couldn't be swapped though there would be a minor hit to efficiency.

*esssentially

Above I said that the construction of the two types of motors is essentially the same. In both cases, AC Induction motor and Brushless DC motor, we are talking about motors that have wound stators instead of permanent magnets. That makes them "Universal motors":

One advantage of having wound stators in a motor is that one can make

a motor that runs on AC or DC, a so called universal motor.

However, there is a slight difference in the winding. Motors designed for use with AC are sinusoidally wound while motors destined to be used with DC are trapazoidally wound. Something that has bugged me for years is that I cannot find a simplified diagram that shows the difference. If I was given the stator of a motor, I would have no idea wether it was wound sinusoidally or trapazoidally. The only way I know of to tell the difference is to back drive the motor by connecting a drill to the shaft and looking at the Back-EMF. You will either see a nice sine wave or more of a trapezoid as shown in the image above. As I said above, using the incorrect type of drive would result in a slight performance hit but it would other wise work.

More often than not, Brushless DC motors are built with permanent magnets on the rotor. While that would be a difference from a squirrel-cage motor, as long as the stator is a wound stator and not a permanent magnet stator (as seen in brushed DC motors), both designs are essentially "universal motors":

The permanent magnet side of the above diagram shows a two pole motor. The number of poles controls the torque ripple. The more poles the smoother the torque curve. But the number of poles makes no difference from an AC versus DC perspective.

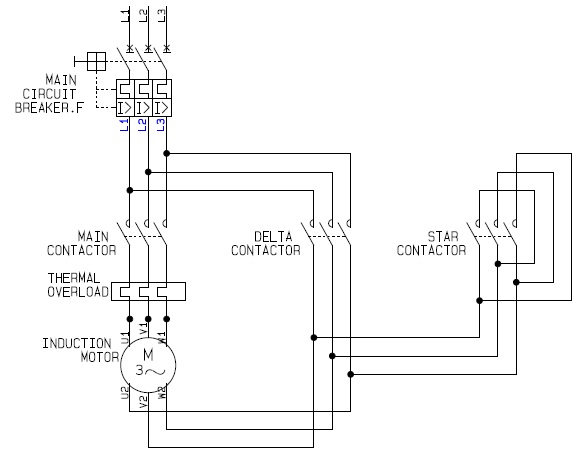

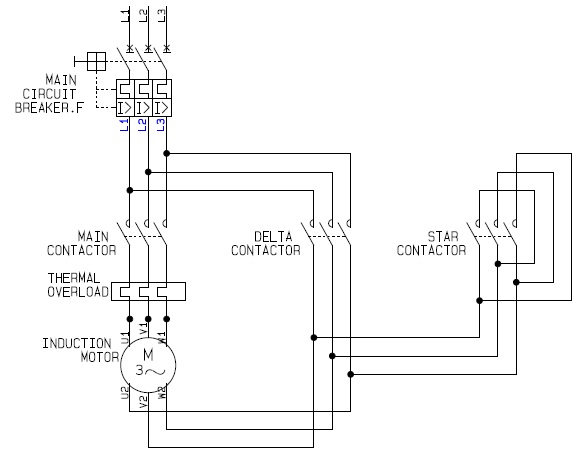

The connection of the stator windings, delta versus star, also does not affect the drive method. And in fact, you can switch between the two while it's running:

The difference there is that delta will draw more current and therefore produce more torque. For more information on the relationship or current to torque or voltage to speed, see my answer to this EE.SE question.

Best Answer

I once used a spectrometer that was just a grating on a rotation stage. It had a worm gear drive and a stepper motor turning the worm gear. Given different worm gears and stepper motrs you can get very fine resolution. The problem is then repeatably. There is gear back lash which can be removed by always going in the same direction. And then finally you'll need a way to set a zero point. For the spectrometer this was done by observing the zeroth order reflection from the grating. You could do a similar optical thing. Or perhaps a mechanical limit switch. Once you have zero getting to any angle is just a matter of counting pulses into the stepper.